Published January 11, 2024 | 7 minute read

Published January 11, 2024 | 7 minute read

If you’re a plant manager or maintenance technician working with rotating equipment, you know how important it is to keep bearings in prime condition.

Essential for enabling smooth and efficient operation of your industrial equipment, bearings are also prone to lubrication-related failures, contamination, overloading, and improper handling and installation.

Bearing failure is a maddening occurrence, causing unexpected downtime, unnecessary damage, and increased costs for your plant.

Lip seals are a traditional option designed to prevent such bearing failure. However, they have many drawbacks that impact the overall performance and reliability of your equipment, such as shaft wear, seal deterioration, heat generation, and moisture exchange, to name a few.

Fortunately, bearing isolators offer a way to overcome these challenges.

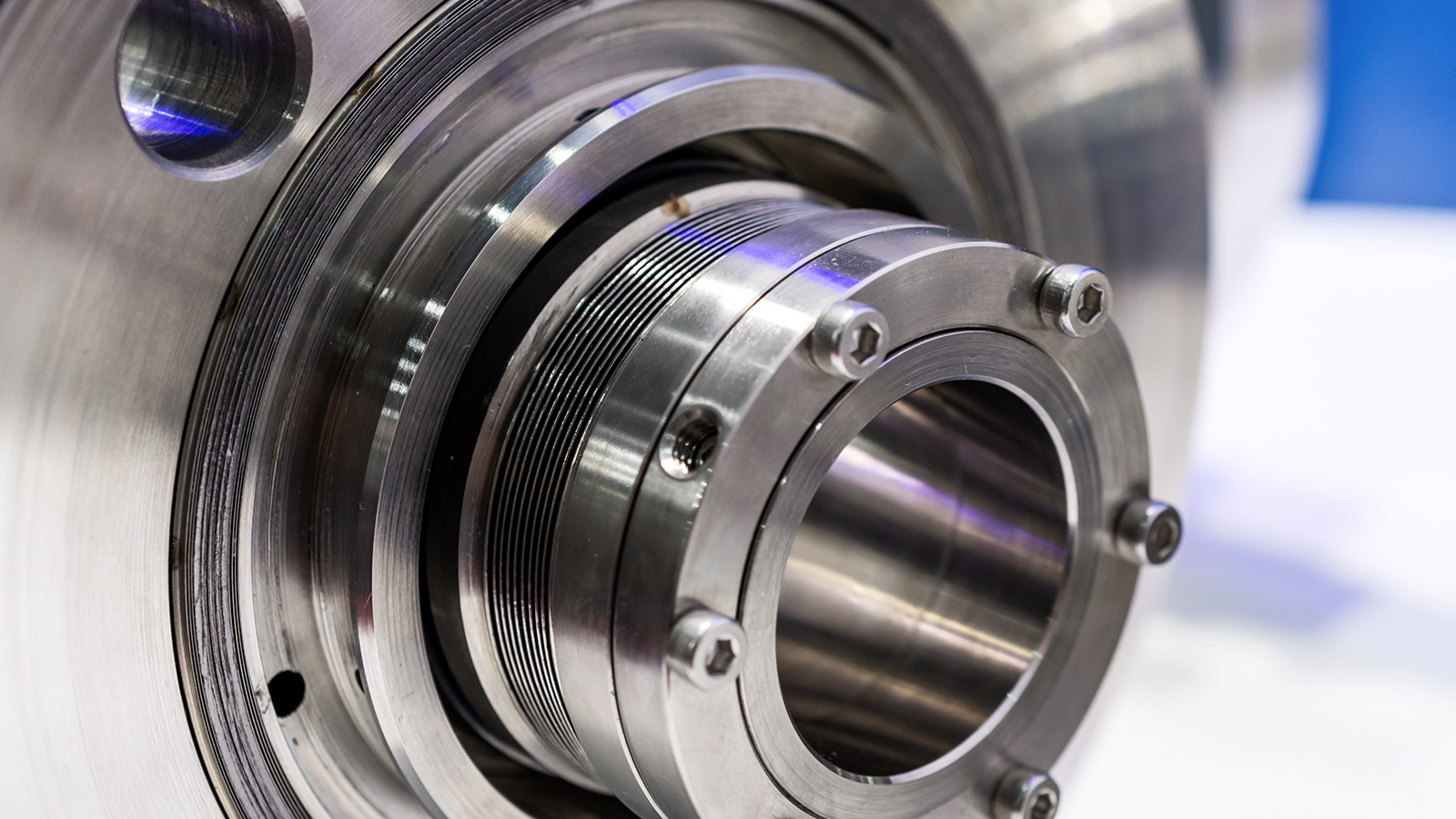

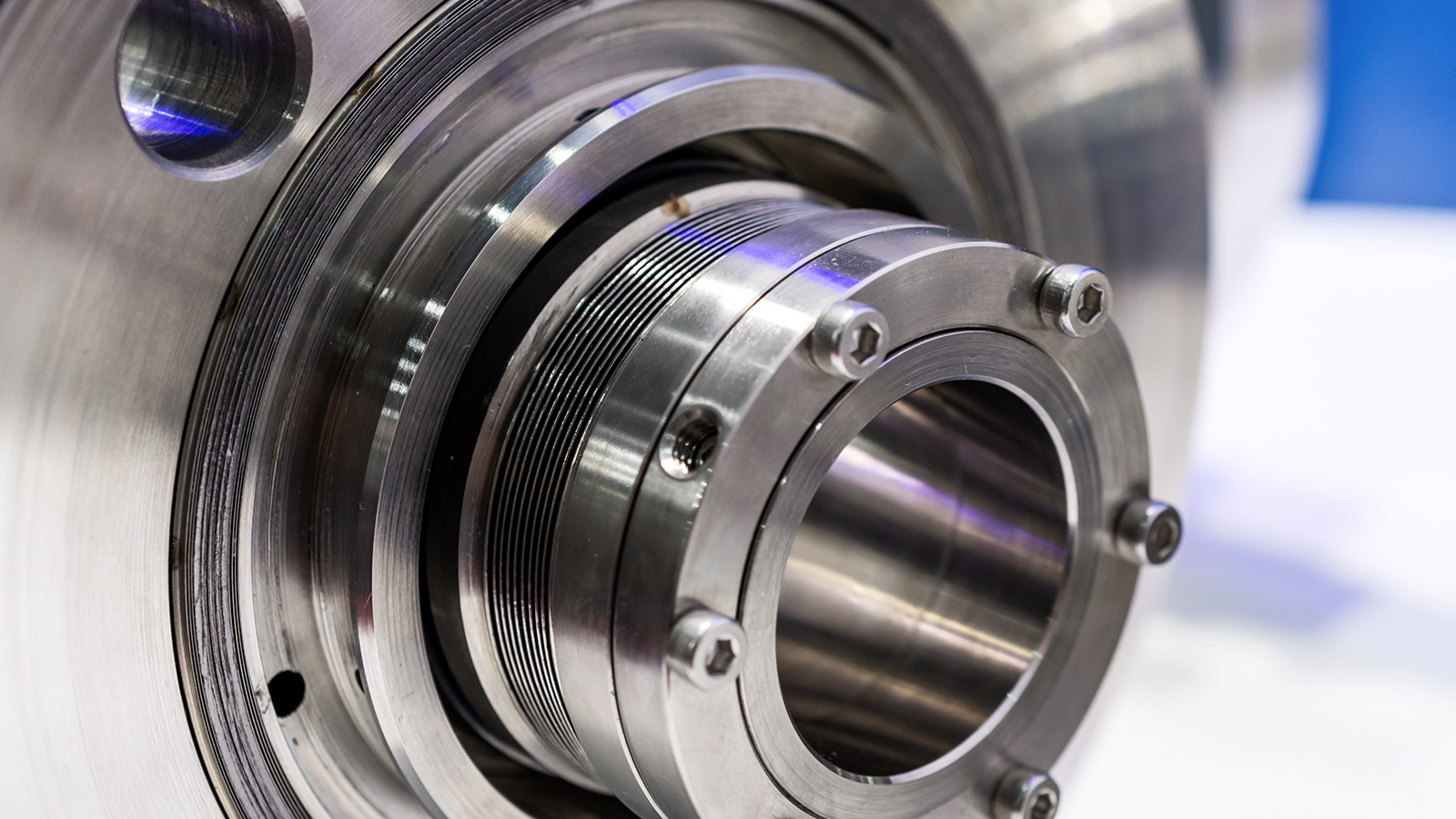

Bearing isolators can be of a non-contacting or contacting type. The non-contacting labyrinth seal features rotating and stationary components with a small operating air gap between them that creates a tortuous or labyrinthine path to impede lubricant egress and contaminant ingress.

Contacting bearing isolators are similar to mechanical seals, with a contacting rotary and stationary face combination that creates a hermetic seal. Most have their closing forces generated by magnets due to their small cross-section, but some larger contacting bearing isolators use springs.

Let’s look further into the causes of bearing failure, problems with lip seals, and benefits of switching to bearing isolators, of which one manufacturer stands out above the rest.

Bearing failure is a common problem that can affect the performance and steadfastness of your rotating equipment. Some of the most frequent failures result from:

This leads to excessive friction, wear, heat, and metal-to-metal contact, which can damage the bearing surfaces and shorten bearing life. Lubrication is essential for supporting machinery elements under load, minimizing wear, dissipating heat, preventing corrosion, and flushing out contaminants.

To curtail lubrication failure, you should use the right type and amount of lubricant for your industrial application, follow the recommended relubrication intervals, and avoid grease loss or contamination.

This occurs when foreign particles such as dirt, dust, grit, water, or chemicals enter the bearing lubricant or the bearing itself. These elements get into the bearing housing due to short-lived lip seals or routine changes in temperature coupled with inadequate filter breathers. (To explore upgrading your filter breathers, check out Des-Case).

Contamination causes abrasive wear, corrosion, spalling, denting, and increased noise and vibration. It also affects the lubricant’s viscosity and film thickness, which can diminish lubrication effectiveness.

Abrasive wear grinds away material from the bearing surfaces due to scraping between the particles and metal. This lowers the bearing’s load capacity, accuracy, and smoothness. It also creates asperities, or surface imperfections, that eventually come in contact, interrupting the film of lubricant.

Corrosion is the chemical reaction between the particles and metal that leads to the formation of rust or oxides. This impairs the bearing’s strength, increases friction, and creates more debris.

Denting pertains to the creation of small pits or indentations on the bearing surfaces due to the impact of particles. This can alter the bearing’s geometry, clearance, and alignment, increasing noise and vibration.

Particle contamination can also affect your lubricant’s viscosity and film thickness, the properties that determine its ability to form a protective layer between bearing surfaces. Likewise, this undermines lubrication effectiveness, increases friction and heat, and accelerates wear.

To curtail contamination, you should keep the work area, tools, and hands clean, use shields, filter the lubricant, replace the lubricant regularly, and consider replacing lip seals with bearing isolators.

When the applied load exceeds your bearing’s capacity, it causes excessive stress, deformation, and fatigue. Overloading results from improper design, incorrect selection, misalignment, or shock loads. It can also cause premature failure, increased temperature, and diminished lubrication.

To prevent overloading, choose the right bearing size and type for your industrial application. This establishes proper alignment and mounting and avoids sudden or excessive loads.

Physical damage to the bearing components such as dents, scratches, cracks, or brinelling results from reckless handling and incorrect installation. Other contributors include using excessive force, applying pressure or blows to the wrong race, using incorrect tools, or having loose or tight fits. Improper handling and installation can also affect your bearing’s performance, alignment, and clearance.

To minimize this, you should follow the manufacturer’s instructions, use appropriate tools and methods, and verify it fits properly.

The Problems With Lip Seals

Traditionally, lip seals have been the most common way to protect bearings. This is done by creating a contact seal that relies on friction between the seal lip and the shaft, forming a barrier against lubricant leakage and contaminant ingress.

Lip seals usually fail to prevent particle contamination and generate several problems over time:

Lip seals remain popular because of their lower upfront cost, although over time they can become costly due to premature bearing failure.

Bearing isolators, on the other hand, can overcome these problems by providing a non-contacting or contacting seal that prevents air and moisture exchange without damaging the shaft or losing sealing effectiveness. And they do this while generating little to no heat and without consuming power.

Put simply, bearing isolators can effectively prevent both moisture and particle ingress, which are the main causes of bearing failure.

Bearing isolators can extend your bearing’s life and improve the efficiency and reliability of your equipment. They can last five years or longer, while lip seals typically have a life expectancy of less than six to 12 months.

Non-contacting bearing isolators use labyrinth technology, which creates a non-contact seal between the shaft and the housing, with a tortuous path between them to exclude and expel contaminants.

Alternatively, contacting bearing isolators are similar to mechanical seals, with a contacting rotary and stationary face combination that creates a hermetic seal. Most have their closing forces generated by magnets due to their small cross-section, but some larger contacting bearing isolators use springs.

Notably, bearing isolators meet the requirements of various industry standards, such as IEEE 841-2001 for electric motors or API 610 12th edition for pumps. They can also be customized for different types of rotating equipment, such as pumps, motors, gearboxes, steam turbines, and compressors.

Don’t settle for anything less than industry-pioneering bearing isolators when looking to keep your lubricants clean and dry while protecting your bearings.

AESSEAL is one of the leading specialists in the design and manufacturing of mechanical seals and support systems. Their innovative lines of LabTecta and MagTecta products feature a wide selection of specially designed seals that include patented features to help safely contain and prevent liquids and gasses from escaping.

Both product lines are carried and distributed by Sunair, a team of seasoned veterans helping engineers find the right industrial equipment and products for their high-demand projects since 1974.

The innovative LabTecta product range features an advanced labyrinth design that facilitates the proper ventilation of the bearing housing during shaft rotation, while effectively sealing it when the shaft comes to a stop.

Its non-contacting design ensures zero wear on the machinery shaft, enhancing its performance and ensuring longevity. The standard models offer IP66 ingress protection, as well as IP69K protection available with the LabTecta OP series, specifically designed to inhibit water ingress and oil egress.

AESSEAL also offers a range of cutting-edge MagTecta bearing protection devices designed to effectively safeguard your pump equipment, even in the most challenging and demanding operating environments.

MagTecta’s state-of-the-art products feature magnetically energized contacting faces, ensuring exceptional protection against external contamination while preventing any lubrication loss.

They’re particularly well suited for oil mist (pure mist) applications, and because they’re non-wearing, won’t require routine maintenance—guaranteeing reliable and long-lasting protection.

These seals feature a unique oil mist collecting and retainment system for improved seal life and are available in a range of sizes, from 0.750” to 5.875” (16mm - 145mm), with larger sizes 6.000” to 12.000” (150mm - 300mm) also available upon request.

These versatile seals incorporate labyrinth seal technology to defend your equipment from both external contamination and loss of lubrication, and are utilized for:

Our fully equipped service center is factory authorized to service all the AESSEAL bearing isolators you need to keep your industrial equipment running at full capacity. 24 hours a day, 365 days a year.

To learn more about the bearing isolators Sunair Co. carries, contact us today.

Receive the latest industry news, once a month. Unsubscribe anytime.

To determine the size of a component mechanical seal, measure the inside diameter of the seal face, the length of the spring, and diameter and thickness of the stationary seat.

Read NowDesigned to handle various hydrocarbons in accordance with the high standards of the American Petroleum Institute, API pumps ranging from end suction to vertical turbine models are commonly used in the petroleum, petrochemical, and natural gas industries.

Read NowAir-operated double-diaphragm (AODD) pumps utilize compressed air and dual chambers to transport fluids safely and efficiently in support of a wide range of industrial applications.

Read NowSunair Co. carries high-quality propane pumps and compressors from leading manufacturers such as Sundyne, Blackmer, and National Pump to ensure your operations perform safely and effectively.

Read NowRegularly inspecting your mechanical seals and monitoring various factors that could contribute to failure or leakage will help extend their lifespan, while ensuring operational efficiency and safety.

Read Now2475 Wyandotte Road

Willow Grove, PA 19090

Phone: (215) 657-9800

Fax: (215) 657-9881

Email: sunairco@sunair.com

© Copyright 2025 Sunair Co.

Logos on this page are copyrights of their respective companies. The Sunair logo is a registered trademark of Sunair Co.

Leave a comment