Published November 19, 2021 | 3 minute read

Published November 19, 2021 | 3 minute read

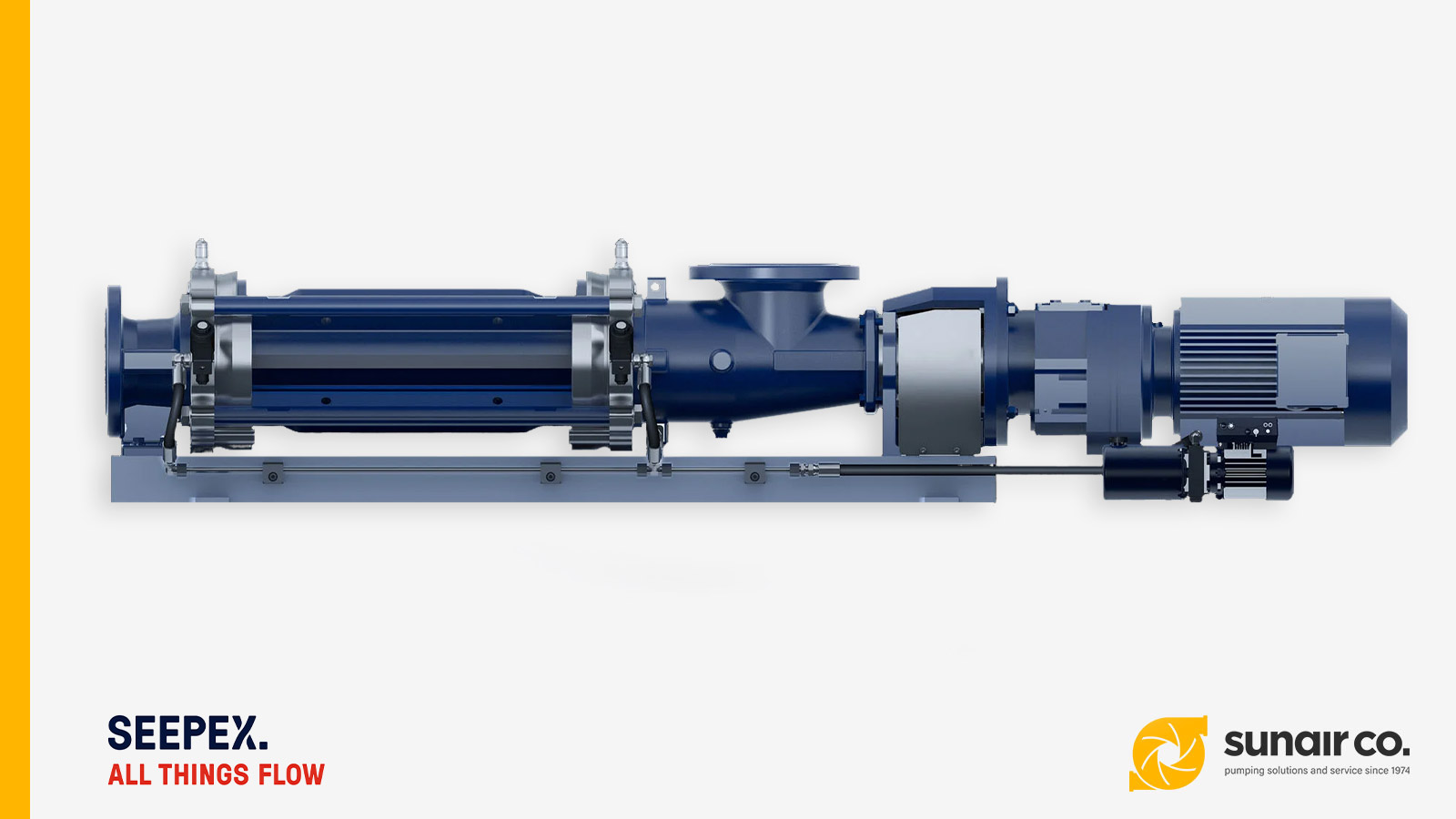

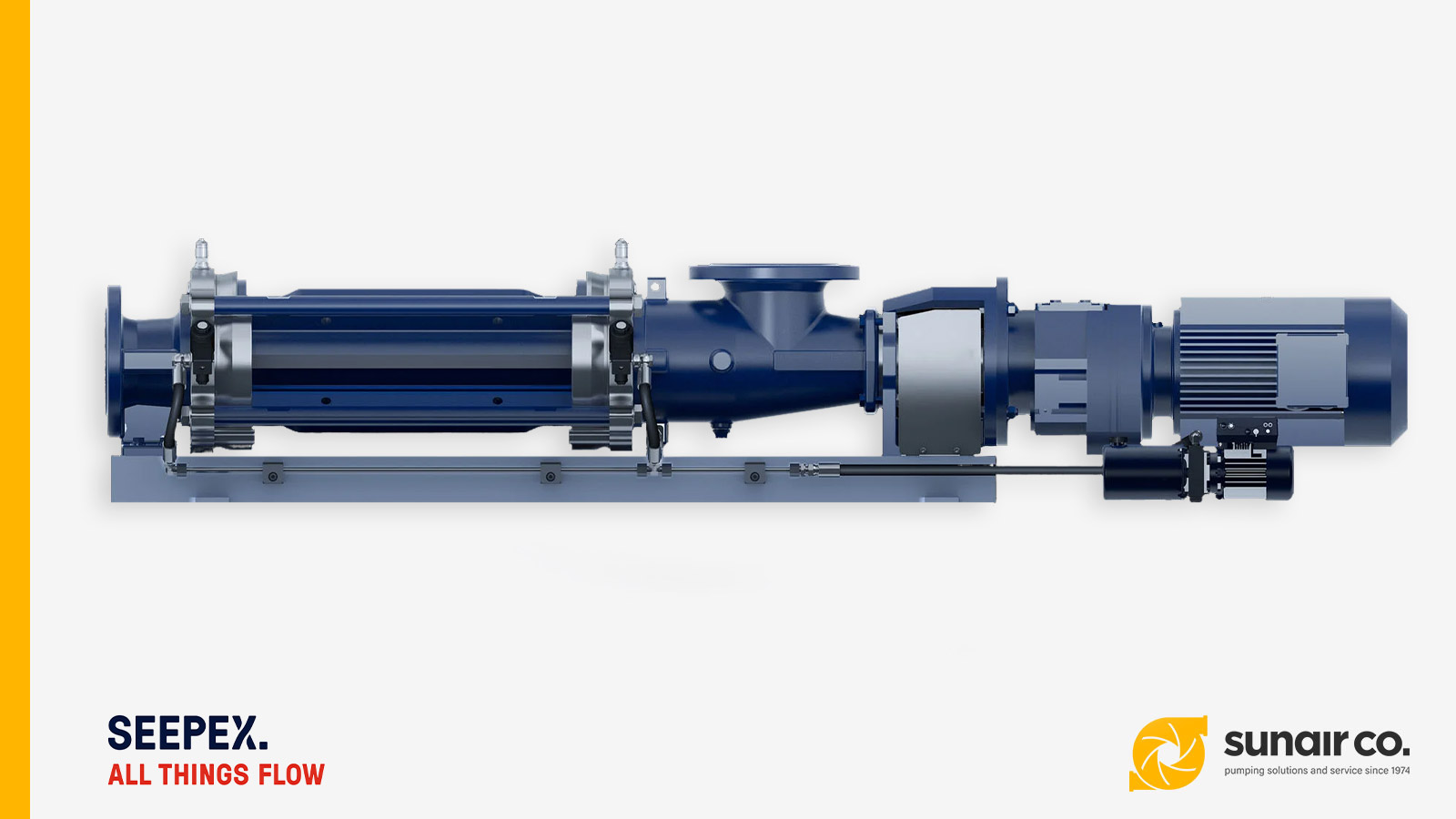

No matter what your industry or application, if you require a progressive cavity pump to keep operations running smoothly, the SEEPEX product line is up to the task.

SEEPEX is one of the leading manufacturers of progressive cavity pumps, macerators and pump control systems in the world. Their advanced designs provide pumping solutions that handle varying levels of viscosity and abrasiveness—for whatever your job requires.

SEEPEX’s powerful and durable progressive cavity pumps use strong suction forces for easy transport of materials ranging from low-viscosity to highly viscous media, with or without solids, as well as air- or gas-liquid mixtures.

Utilizing low pulsation, these pumps deliver a steady, even flow without the need for separate dampeners or compensators, and have low shear—making them ideal for handling more sensitive substances.

SEEPEX pumps feature a variety of rotor and stator shapes and sizes, as well a wide range of shaft seal configurations, making the equipment easy to adapt and tailor to suit any conveying process.

The pumps are available fitted with a variety of pressure connection types to suit your application, including flanges, NPT, open hopper, and sanitary openings for the simple intake of clean or solids-containing media. This makes SEEPEX pumps suitable for use in virtually any industrial application, from wastewater to chemical to food production to refining.

SEEPEX pump designs are created with ease of installation and upkeep in mind, enabling horizontal or vertical positioning with a large, rotatable, spherical suction intake, depending on your on-site layout conditions.

The pinnacle of SEEPEX’s innovative equipment is the patented Smart Conveying Technology (SCT). Developed exclusively by SEEPEX in 2008, SCT provides the most effective pumping solutions, as well as unparalleled ease, customization, and productivity to your operations.

The SEEPEX SCT line has a unique design enabling the sealing line between the rotor and stator to be adjusted for the required application, while also compensating for wear. This typically more than doubles the life of the rotor and stator, while ensuring the fastest possible maintenance — reducing downtime and significantly lowering life cycle costs across virtually all market sectors.

Additionally, SEEPEX offers a SCT Retrofit-Kit, enabling an existing conventional tube stator pump to be upgraded without modifying the pipework or base plate—making it even easier to install and optimize for your operations. Utilizing the innovative equipment of the SCT system is a smart, convenient, and cost-effective way of guaranteeing your pump solutions will be as effective as possible, for as long as possible.

SEEPEX customers know their pumps can handle even the most complex of applications.

Receive the latest industry news, once a month. Unsubscribe anytime.

To determine the size of a component mechanical seal, measure the inside diameter of the seal face, the length of the spring, and diameter and thickness of the stationary seat.

Read NowDesigned to handle various hydrocarbons in accordance with the high standards of the American Petroleum Institute, API pumps ranging from end suction to vertical turbine models are commonly used in the petroleum, petrochemical, and natural gas industries.

Read NowRegularly inspecting your mechanical seals and monitoring various factors that could contribute to failure or leakage will help extend their lifespan, while ensuring operational efficiency and safety.

Read NowPairing Sunair Co.’s high-quality equipment with the most impactful automation opportunities within the food manufacturing industry—across the packaging, production, sanitation, product tracing, and quality control phases—enables companies to realize significant operational efficiencies and cost savings.

Read NowSunair Co. carries high-quality propane pumps and compressors from leading manufacturers such as Sundyne, Blackmer, and National Pump to ensure your operations perform safely and effectively.

Read Now2475 Wyandotte Road

Willow Grove, PA 19090

Phone: (215) 657-9800

Fax: (215) 657-9881

Email: sunairco@sunair.com

© Copyright 2025 Sunair Co.

Logos on this page are copyrights of their respective companies. The Sunair logo is a registered trademark of Sunair Co.

Leave a comment