- Versatile Applications: Processing pumps are essential in the food and beverage industry for tasks within liquid transfer, mixing, filtration, and clean-in-place systems.

- Two Major Pump Types: Choose between centrifugal pumps for low- to moderate-viscosity fluids and positive displacement pumps for high-viscosity, shear-sensitive products.

- Hygienic Standards: Pumps in food processing must meet stringent hygienic requirements, often be constructed with food-grade materials, and be certified by regulatory bodies such as 3-A SSI or EHEDG.

- Specialized Designs: Some applications require specialized pump designs or materials to meet specific hygienic, corrosion resistance, or compatibility needs.

- Comprehensive Solutions: Partnering with Sunair ensures access to top-rated pumps, along with expert installation, repair, and maintenance services—optimizing your food and beverage operations.

Integrating the wrong processing pumps into your food and beverage production will compromise product integrity and result in inefficient pumping operations.

If your foods or beverages aren’t matched with the right processing pump, you’ll encounter frequent downtime and costly maintenance repairs.

An experienced industrial pump supplier will help you identify the right model for your operations.

How Processing Pumps Are Used in the Food & Beverage Industry

Processing pumps are crucial in the food and beverage industry. They feature in a wide range of applications to automate processes, including:

- Liquid Transfer: Pumps transfer liquids such as juices, syrups, oils, and other ingredients from storage tanks or containers to processing equipment or packaging lines. Centrifugal and positive displacement pumps are employed depending on the viscosity, flow rate, and other characteristics of the liquids transferred.

- Mixing & Blending: In-line pumps are often employed to mix ingredients during the production process. These create a shearing action that helps thoroughly combine different components, ensuring homogeneous mixtures or emulsions.

- Filtration & Separation: Used in filtration systems to circulate liquids through filters or membranes, these pumps separate solids or unwanted particles from your product. This process is also essential for clarifying juices, beverages, and other liquid products.

- Clean-in-Place (CIP) Systems: An integral part of CIP systems, these food and beverage pumps clean and sanitize processing equipment and pipelines. High-pressure pumps circulate cleaning solutions, hot water, and sanitizing agents through the equipment, ensuring thorough cleaning and minimizing the risk of contamination.

- Evaporators & Concentrators: In the production of concentrated products such as juices and syrups, these pumps feed evaporators or concentrators and circulate product throughout the system.

- Filling & Packaging: These pumps transfer products from processing equipment to filling machines or packaging containers.

Each type of food and beverage pump is fine-tuned for accuracy and efficiency, and selected based on the specific requirements of your application, including flow rate, viscosity, temperature, and the need for gentle or shear-sensitive handling of the product.

Proper selection, installation, and maintenance of pumps guarantee efficient operation, product quality, and compliance with stringent food safety regulations within the food and beverage industry.

When purchasing a pump, be certain to consult a trusted manufacturer or distributor. They’ll prevent you from choosing the wrong model or improperly deploying it.

What Kind of Food & Beverage Pump Do I Need?

For most food and beverage applications, you’ll use either a centrifugal or positive displacement pump.

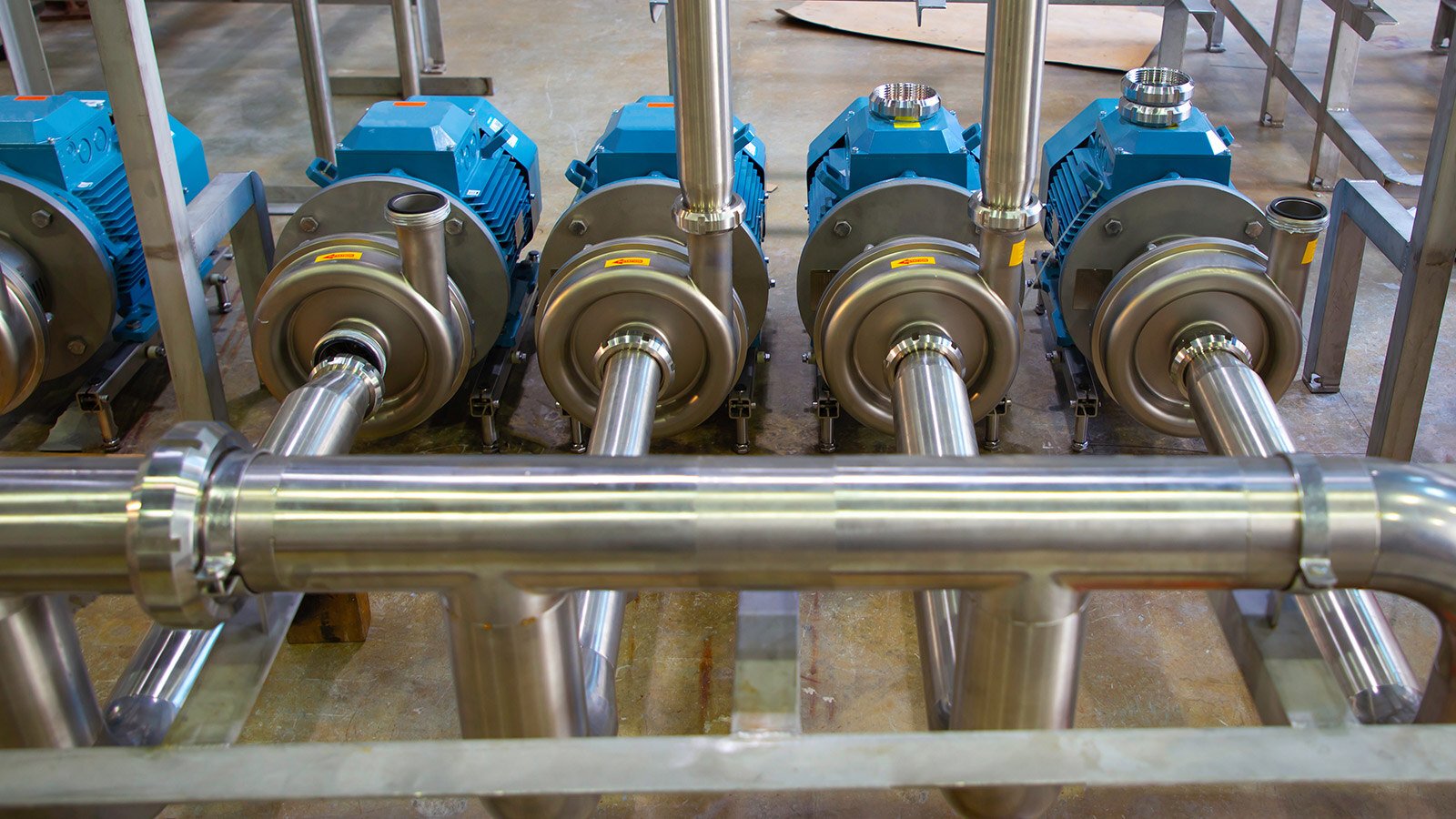

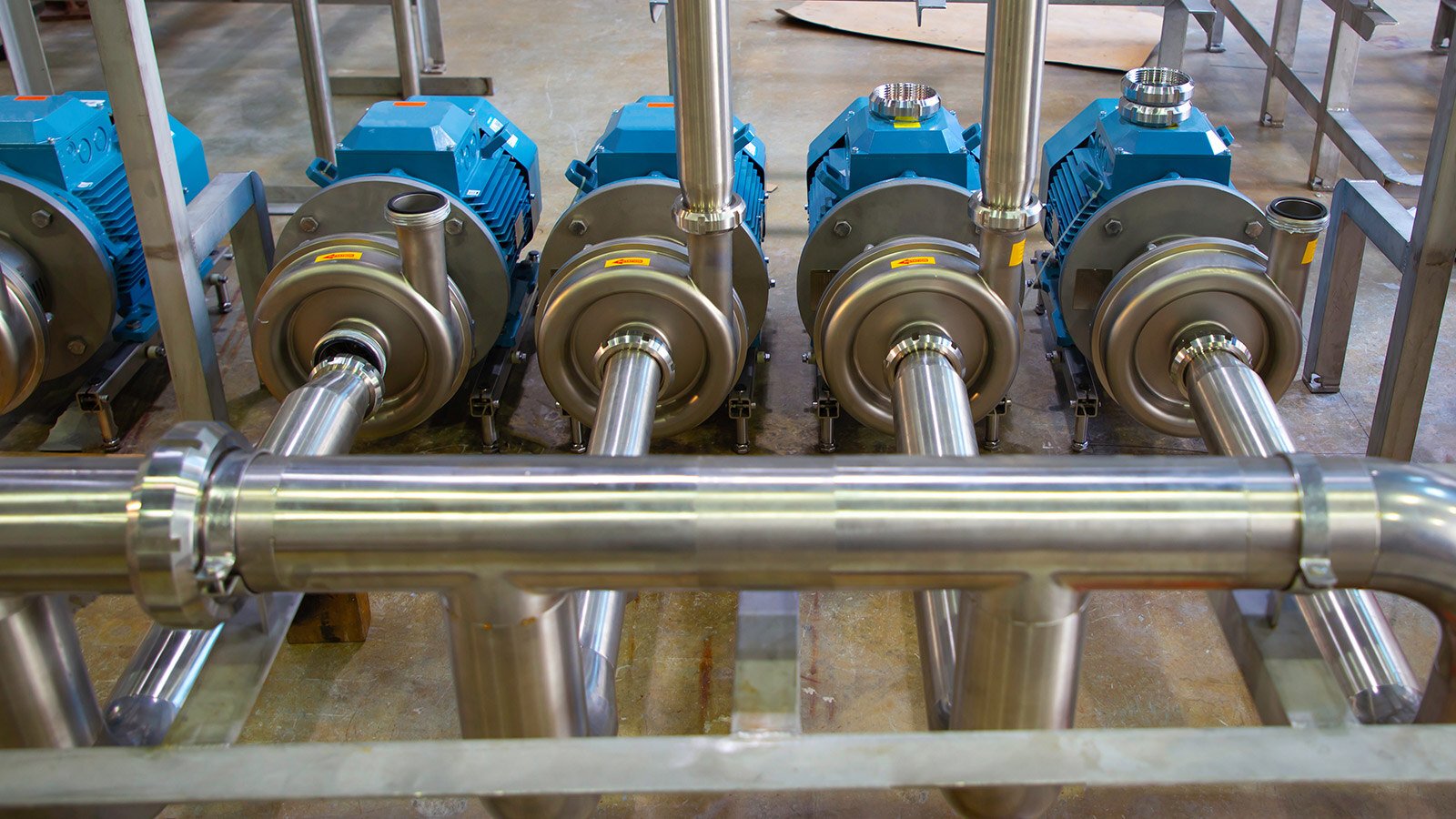

Centrifugal Pumps

Centrifugal pumps utilize an impeller (a rotating component) to transfer energy from a motor to a fluid.

This pushes low to moderate viscosity liquids such as water, juices, and thin syrups through the pump. They are available in single-state and multi-state formations. Centrifugal pumps are preferred in the food and beverage industry because they can handle a wide range of flow rates and viscosities, are relatively easy to maintain and clean, and have a simple but robust design.

In the food processing industry, there are several types of centrifugal pumps commonly used, each designed to meet specific requirements and applications. Here are several main types:

- Designed with smooth internal interfaces and crevice-free construction, sanitary centrifugal pumps meet the strictest hygienic requirements. They are typically made of stainless steel or other food-grade materials, easy to clean and sanitize, and must be certified by either 3-A Sanitary Standards Inc (3-A SSI) or the European Hygienic Engineering and Design Group (EHEDG).Applications: bottled water, beer, wine, liquor, yeast, wort, mash, fruit concentrate, fruit juices, high fructose corn syrup, marinade solutions, and carbonated beverages.

- As their name suggests, self-priming centrifugal pumps can start pumping even when the suction line is not initially filled with liquid. This is useful in applications where your liquid source is below the pump level, or frequent priming is required. Food and beverage companies often utilize these for moving liquids from tanks or sumps. Eliminating the need for manual priming reduces the risk of contamination.Applications: most beverages, oil, and batter operations.

- Vertical centrifugal pumps feature vertically oriented impellers and motor shafts. They’re a great solution for when space is limited or your liquid source is below the pump level.Vertical centrifugal pumps are commonly used in food processing plants for pumping liquids from underground tanks or sumps and transferring juices, concentrates, or other liquid ingredients from storage tanks to blending or filling lines. They can also circulate cooling or heating media (e.g., water, glycol solutions) for temperature control in various food and beverage processing operations.Applications: syrups, concentrates, thick purees, dairy products, and wastewater handling.

- Built with numerous impellers arranged in a series, multi-stage centrifugal pumps generate higher pressures than their single-stage centrifugal counterparts.They are used in applications that require high discharge pressures, such as reverse osmosis systems or high-pressure cleaning applications. They can generate pressures up to several hundred psi, ensuring effective cleaning and sanitation.Applications: pasteurization, high-pressure cleaning systems, water treatment/purification, and concentration of liquids.

- Submersible centrifugal pumps are intended to be dunked in the liquid they are pumping and often used for transferring substances from tanks, sumps, or wells. Their compact structure means they can be easily installed or removed from the liquid source.Applications: transferring liquids from storage tanks or for drainage, brewery and bottle washing, and drinkable liquids.

- Utilizing magnetic coupling instead of a mechanical seal, magnetic drive centrifugal pumps eliminate the need for a dynamic seal. This reduces the risk of leakage. They are suitable for handling hazardous, corrosive, or sensitive liquids, as well as operations in which product contamination must be avoided. Magnetic drive centrifugal pumps are popular in the food processing industry for handling.Applications: dairy processing and beverage production, edible oils, flavors, and other sensitive liquids.

Positive Displacement Pumps

While centrifugal pumps provide a continuous, non-pulsating flow, positive displacement pumps rely on pulsation, with high-pressure peaks during each stroke.

Positive displacement pumps transfer liquids at a controlled rate while maintaining sanitary conditions. They’re ideal for handling shear-sensitive products such as fruit purees, yogurt, and sauces because they provide gentle flow with minimal product degradation.They also offer excellent suction that can handle products with solids or particulates, and come in a few varieties:

- Using compressed air as a power source, air-operated double-diaphragm (AODD) pumps are designed for transferring anything from water to up to 90% solids, such as fruit purees and concentrates. AODD pumps consist of two pumping chambers alternately filled and discharged by the movement of flexible diaphragms.Applications: sauces, syrups, dairy products, beverages, and filling and packaging.

- Peristaltic or hose pumps perform similar to muscles contracting to move fluids through a tube. Since only liquid touches the interior tube, food or beverage products remain completely unsullied. Peristaltic pumps’ low-shearing mechanism and contractive motion make them ideal for operations requiring accurate dosing or metering.Applications: fruit purees, yogurt, delicate emulsions, adding ingredients/flavors/additives, sauces, dressings, and aseptic processing.

- Hydraulic diaphragm pumps rely on hydraulic fluid between a piston and diaphragm to move liquids. A built-in safety mechanism means there’s no need for relief valves and other devices for handling abnormal pressure, which makes hydraulic diaphragm pumps adept for use with fluids you don’t want exposed to free air. Applications: sauces, jellies, jams, beer, wine, concentrates, high viscosities, yogurt, mayonnaise, emulsions, adding ingredients/flavors/additives, and acidic or caustic fluids.

- In piston pumps, the drawing or pushing out action is achieved by the reciprocating movement of a piston or plunger within a cylindrical chamber. With each stroke, the piston or plunger alternately draws in and displaces a fixed fluid volume.They are employed for accurately dosing or metering ingredients such as flavorings, colors, or preservatives. They’re popular among food and beverage companies because they provide precise flow control and repeatable dosing.Due to their versatility and ability to handle a wide range of products, piston pumps are often utilized in pilot plants and small-scale food and beverage production facilities for testing or producing small batches.Applications: food pastes, sauces, creams, and dairy products.

- Using rotating gears to move fluids, rotary pumps are another popular option for handling viscous food substances without damaging or altering their properties. Rotary pumps are comparatively easy to maintain, and feature sanitary construction. Applications: creams, sauces, wine, slurries, and fruit concentrates.

- Screw pumps utilize screw-shaped rotors that intermesh and rotate together to capture and transfer liquids, available in one- to five-screw configurations. Also known as progressive cavity pumps, single screw pumps, such as the Seepex model N and SCT series, are ideal for handling wastewater sludge and other hard-to-pump materials.Twin screw pumps are characterized by their consistent flow and pulsation-free, low-shear pumping action. They transfer a diverse array of fluids containing solids with very low rates of product or ingredient damage. They can also automate food manufacturing operations, such as unloading ingredients from drums and storage systems, and more.Q-Pumps’ model QTS twin screw pump, for example, is great at handling fluids with varying viscosities, ranging from 1 cP to 1,000,000 cP, as well as fluids with a high degree of entrained air.Applications: edible oils, meat, dough, glycerine, ointments, sauces, fruit purees, pastes, slurries, and products containing suspended solids or particulates.

Ultimately, your selection of the appropriate type of centrifugal or positive displacement pump depends on the specific food product being handled, required flow rate, pressure requirements, viscosity, temperature, and hygienic standards.

Working closely with veteran pump manufacturers and distributors when considering specific application requirements ensures optimal performance and compliance with food processing regulations.

They’ll take the guesswork out of the selection process, as well.

Centrifugal Pumps vs. Positive Displacement Pumps

The choice between a centrifugal pump or positive displacement pump for food processing applications depends on the type of fluid, required flow rate, pressure requirements, and the specific application.

It all goes back to their different mechanical properties.

Centrifugal pumps are generally preferred for food processing applications involving low to moderate viscosity fluids, such as water, juices, syrups, and other liquids with viscosities similar to or lower than that of water. They are well suited for applications that require a continuous, non-pulsating flow, such as liquid transfer, filtration, and circulation systems.

Centrifugal pumps are also easier to clean and maintain, which is essential in the food industry, where hygiene and sanitation are critical.

On the other hand, positive displacement pumps are better suited for handling high-viscosity fluids, such as thick sauces, pastes, or slurries, which can be challenging for centrifugal pumps. Positive displacement pumps also provide a more precise and consistent flow rate, making them suitable for applications that require accurate metering or dosing, such as filling or packaging operations.

General Guidelines for Pump Selection

- Use centrifugal pumps for:

- Low to moderate viscosity liquids (up to around 1,000 cP)

- Continuous flow applications (e.g., liquid transfer, filtration, circulation)

- Applications with varying flow rate requirements

- Use positive displacement pumps for:

- High viscosity fluids (above 1,000 cP)

- Precise metering or dosing applications

- Applications requiring a consistent, pulsating flow

- Handling shear-sensitive fluids

It's important to note that some food processing applications may require specialized pump designs or materials to meet specific requirements, such as hygienic standards, corrosion resistance, or compatibility with certain food products.

Consulting with pump manufacturers or experts in the food processing industry will help you select the most appropriate pump type and design for your specific application.

Sunair Supplies Top-Rated Food & Beverage Pumps

Sunair carries an extensive selection of premier food and beverage pumps from the most trusted manufacturers in the industry—for all of your food and beverage operations needs.

Partnering with Sunair ensures you’ll acquire the best pump for your particular situation.

We provide the best industrial pumps and reliability equipment on the market, along with a broad suite of associated services, including expert installation, repair, and maintenance services, to help your operations run better, for longer.

For more information about our extensive list of top-quality pumps and equipment, or to learn how to improve your food and beverage operations, contact Sunair today.

Leave a comment