Published July 15, 2021 | 3 minute read

Published July 15, 2021 | 3 minute read

AODD pumps are powerful, durable, versatile, and capable of handling virtually any process fluid, from water to viscous, volatile, and even hazardous liquids when properly applied.

Here is a basic primer on AODD pumps and how they function.

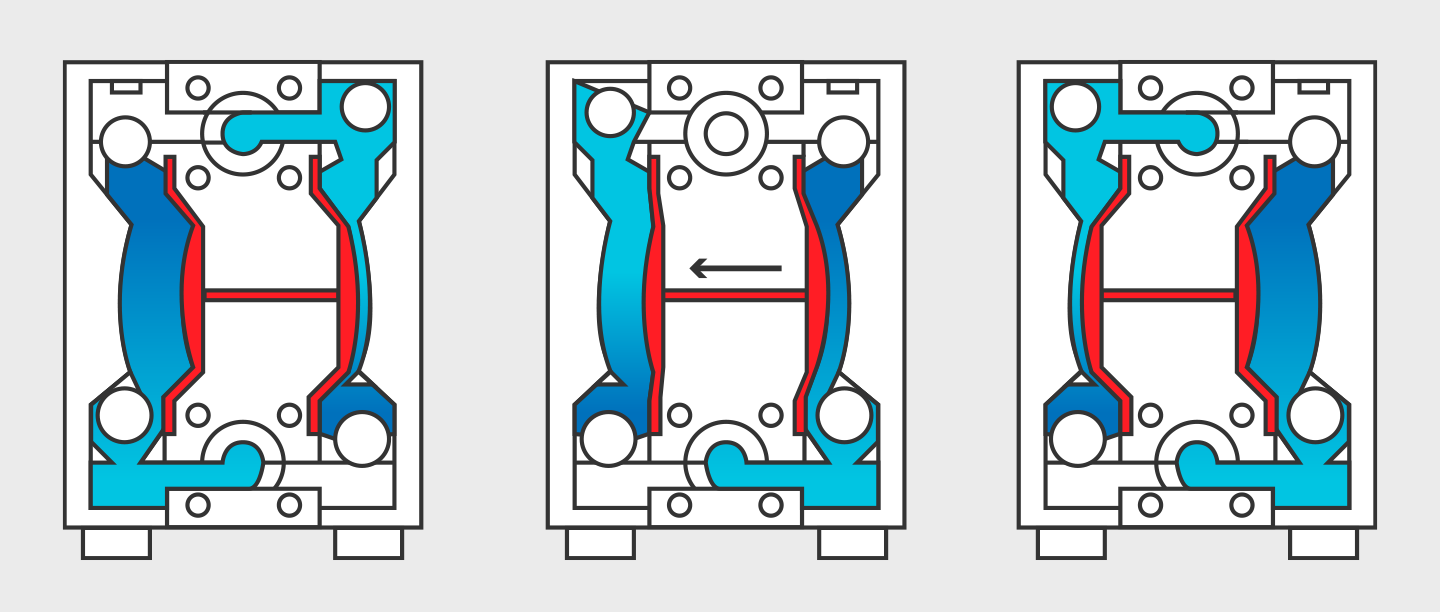

An air-operated double-diaphragm (AODD) pump is a positive displacement pump that utilizes compressed air by acting on a pair of reciprocating elastomeric diaphragms that alternately “pull and push” fluids or flowable powders through a valve system/pumping chambers and out of the pump’s discharge.

It transports fluid using two diaphragms, each separating the motive air from the fluid being pumped. Each diaphragm has its own pump chamber where it generates expanding and contracting cavities of fixed volume displacement. The rate is determined by the speed of the pump’s integral air valve mechanism delivering and exhausting air from the air chambers that fill and empty the cavities.

Due to their unique design, AODD pumps are perfect for transferring thin liquids, as well as highly viscous or abrasive fluids, with ease.

Compressed air shifts between the two flexible chambers — each with an inlet and outlet check valve, as well as a diaphragm mounted on a connecting rod — pulling and pushing liquid along.

Both diaphragms operate simultaneously in parallel oscillation, forcing fluid out through the discharge pipe. The back-and-forth motion of the air fluctuating from one chamber to another works in concert with pairs of suction and discharge check valves on each chamber. The check valves alternately open and close to allow simultaneous filling of one chamber, while the opposite chamber discharges at a speed dependent on the air supply.

Since these pumps rely on a supply of compressed air to function, they are generally restricted to pumping fluids at pressures at or below those of the available air supply. Despite this modest limitation, AODD pumps are known for being robust, versatile, and capable of handling many types of liquids, including highly abrasive, viscous, and shear-sensitive fluids, sludges, and slurries. Because of their gentle pumping action, they are also frequently used to pump shear sensitive fluids such as latex based resins, paints, coatings, and polymers.

There are significant benefits in using an AODD pump. Their general versatility and ability to safely transfer anything from water to solid-laden fluids and even compatible chemicals is invaluable across many industrial applications.

These pumps have no rotating shaft and no mechanical seals or packing, so they can run dry. Because they’re powered by compressed air, they do not require electricity, making them portable and suitable for operation in hazardous environments when properly optioned and applied.

The diaphragms are also more durable and suffer less wear than similar mechanically driven pumps, due to the pressure balancing by the compressed air supply. With no complex internal seals or components requiring lubrication and cooling, an AODD pump can be dry operated for extended periods of time without damage and with little maintenance requirement.

The pump’s design enables it to manage tasks and applications in unique ways:

AODD pumps are renowned for their flexibility, reliability, and cost effectiveness, making them extremely popular and widely utilized across various industries.

Some of the industries employing these pumps include automotive, paints and coatings, ceramics, chemical processing, construction, food and beverages, mining, oil and gas, paper production, pharmaceutical, and water and wastewater treatment.

When it comes to finding the right AODD pump to suit your purposes, Sunair Co. has just what you need. An industry-leading industrial pump, gas compressor, and reliability product distributor, we’ve been supplying high-quality commercial and industrial equipment to businesses and organizations of all sizes, for all industries and applications, since 1974.

Our sales team consists of experienced, knowledgeable experts who design custom systems to ensure you have exactly what you need to keep your operations running smoothly and efficiently.

Receive the latest industry news, once a month. Unsubscribe anytime.

To determine the size of a component mechanical seal, measure the inside diameter of the seal face, the length of the spring, and diameter and thickness of the stationary seat.

Read NowDesigned to handle various hydrocarbons in accordance with the high standards of the American Petroleum Institute, API pumps ranging from end suction to vertical turbine models are commonly used in the petroleum, petrochemical, and natural gas industries.

Read NowRegularly inspecting your mechanical seals and monitoring various factors that could contribute to failure or leakage will help extend their lifespan, while ensuring operational efficiency and safety.

Read NowSunair Co. carries high-quality propane pumps and compressors from leading manufacturers such as Sundyne, Blackmer, and National Pump to ensure your operations perform safely and effectively.

Read Now2475 Wyandotte Road

Willow Grove, PA 19090

Phone: (215) 657-9800

Fax: (215) 657-9881

Email: sunairco@sunair.com

© Copyright 2025 Sunair Co.

Logos on this page are copyrights of their respective companies. The Sunair logo is a registered trademark of Sunair Co.

Leave a comment