Published July 27, 2023 | 4 minute read

Published July 27, 2023 | 4 minute read

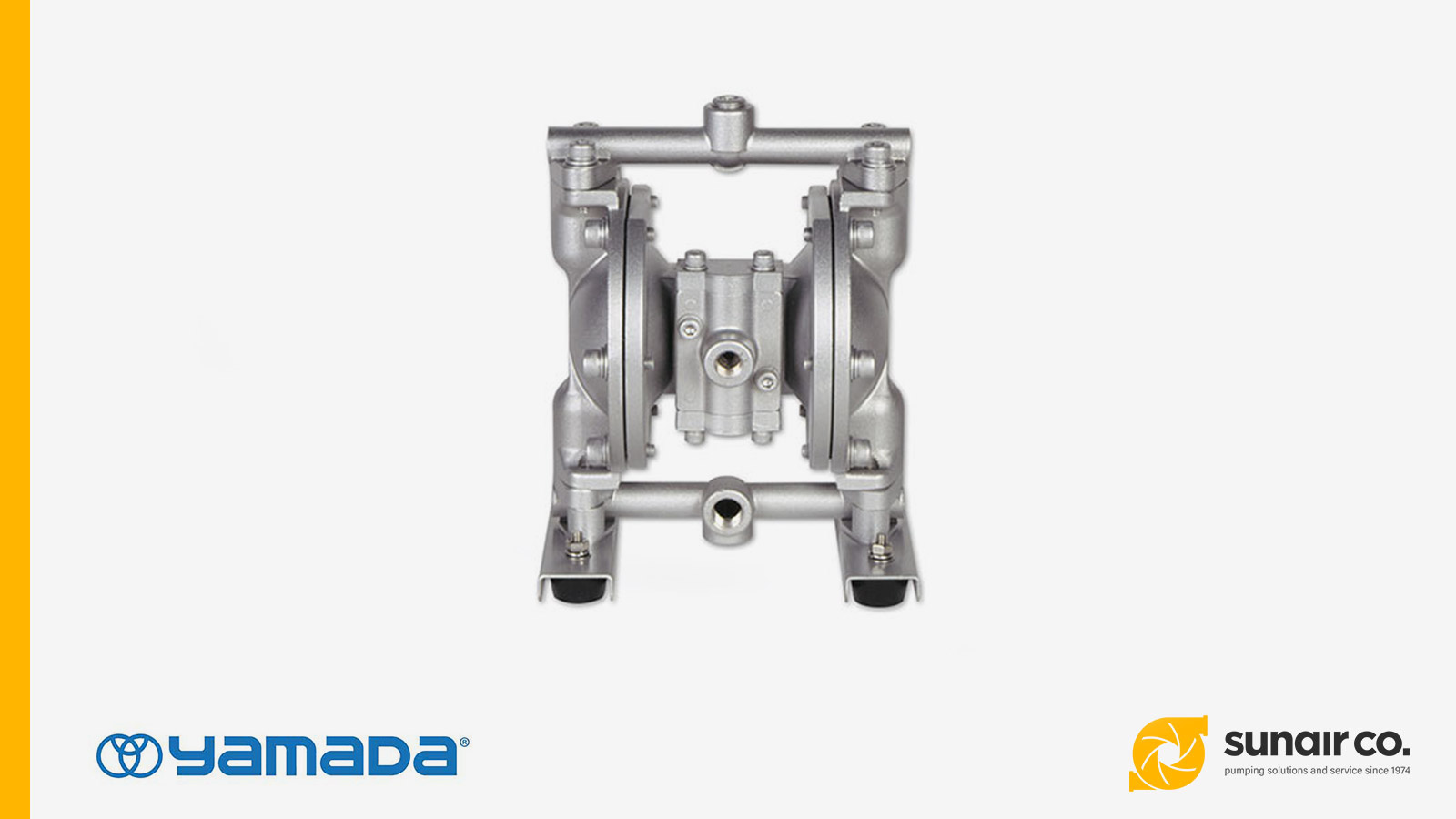

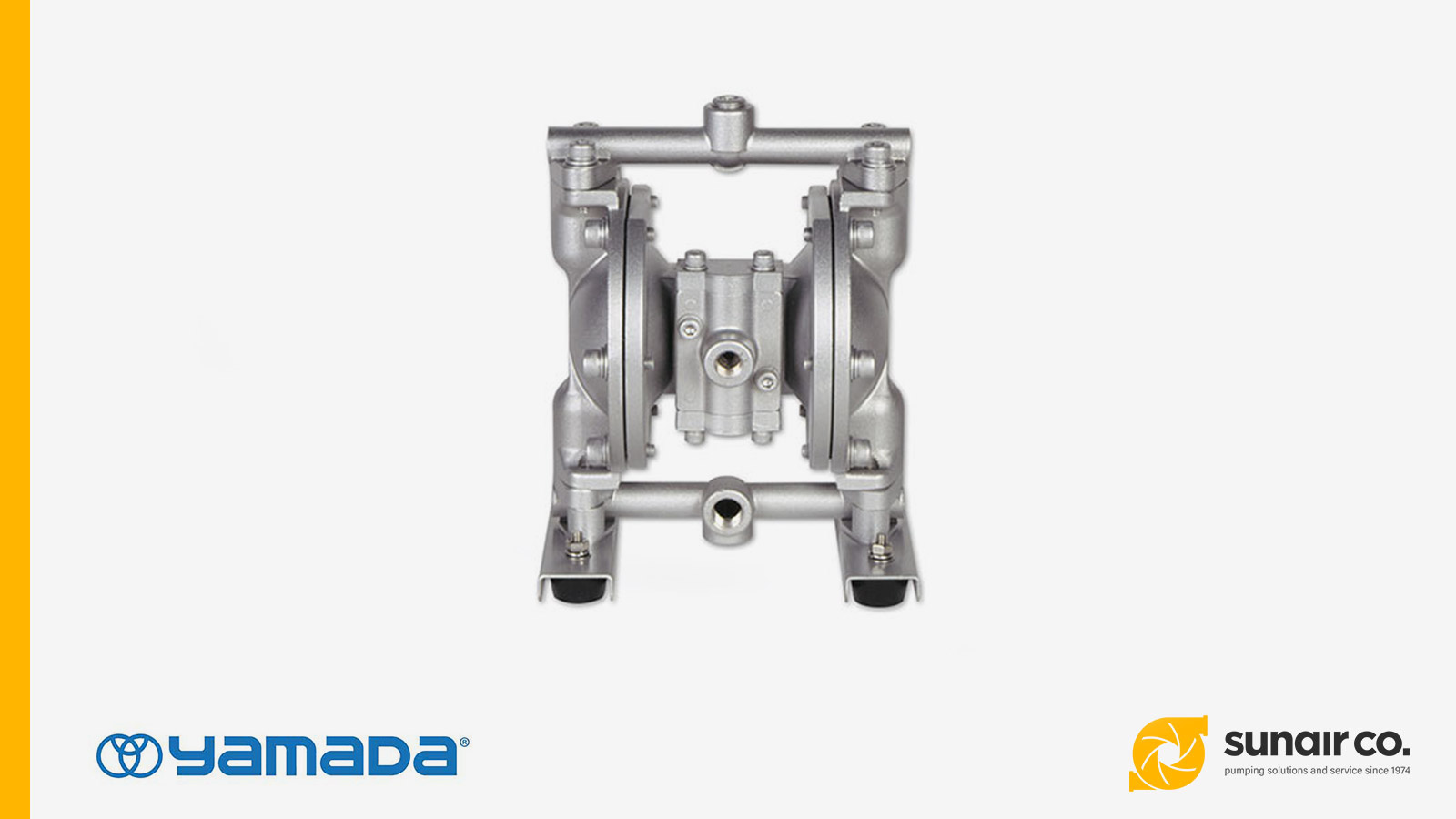

Since 1905, Yamada has established itself as a prominent producer of outstanding industrial equipment, catering to various global industries. Renowned for its commitment to delivering state-of-the-art fluid handling systems, Yamada has become one of the leading manufacturers of air-operated double-diaphragm (AODD) pumps in the world.

Yamada is an ISO 9001-certified manufacturer that develops a wide range of AODD pumps with innovative and durable designs suited for a variety of industrial applications, including chemical transfer, pharma, wastewater, oil and gas, food and beverage pumps, and more.

Sunair carries and services the complete line of Yamada pump products and equipment, and will work with you to identify and install the highest-quality solutions to ensure peak, long-lasting performance for your operational needs.

Yamada pump equipment features exceptional levels of quality and durability, with a diverse range of models to suit your specific applications.

As an ISO 9001-certified company, Yamada adheres to rigorous manufacturing standards to ensure high quality, exceptional performance, and consistency—with every pump undergoing rigorous liquid testing prior to shipment.

All Yamada pumps utilize a unique, patented, non-lubricated air-valve design and are field-proven to provide stall-free operation throughout their entire lifespan. Yamada AODD pumps incorporate an individual modular pilot valve that actuates the air valve for easy use. This also provides outside access to air valves—ensuring you can perform inspections and maintenance without taking the pump out of service.

Its bolted construction provides superior protection against leaks, and makes assembly easier.

Pumps are made from common components with replaceable parts to help maximize uptime and increase profitability.

Double diaphragm pumps can be ordered in various materials depending on their intended applications, including:

Yamada pumps are used throughout industry in markets such as:

Yamada’s main product line comprises state-of-the-art NDP Series Diaphragm Pumps, which include:

Yamada also manufactures a range of specialty pumps designed to cater to industries and applications with specific operating requirements, including:

Sunair Co. is proud to partner with Yamada to carry and support their complete range of pump products.

As a full-service supplier, all Sunair products are backed by our 24/7 service and repair center, which is stocked with a robust inventory of Original Equipment Manufacturer spare and repair parts and manned by an experienced team of factory-trained experts to handle installation, maintenance, repairs, upgrades, and more.

No matter the industry or pump application, you can trust Sunair to keep your applications running optimally, for longer.

Receive the latest industry news, once a month. Unsubscribe anytime.

To determine the size of a component mechanical seal, measure the inside diameter of the seal face, the length of the spring, and diameter and thickness of the stationary seat.

Read NowDesigned to handle various hydrocarbons in accordance with the high standards of the American Petroleum Institute, API pumps ranging from end suction to vertical turbine models are commonly used in the petroleum, petrochemical, and natural gas industries.

Read NowRegularly inspecting your mechanical seals and monitoring various factors that could contribute to failure or leakage will help extend their lifespan, while ensuring operational efficiency and safety.

Read NowPairing Sunair Co.’s high-quality equipment with the most impactful automation opportunities within the food manufacturing industry—across the packaging, production, sanitation, product tracing, and quality control phases—enables companies to realize significant operational efficiencies and cost savings.

Read NowSunair Co. carries high-quality propane pumps and compressors from leading manufacturers such as Sundyne, Blackmer, and National Pump to ensure your operations perform safely and effectively.

Read Now2475 Wyandotte Road

Willow Grove, PA 19090

Phone: (215) 657-9800

Fax: (215) 657-9881

Email: sunairco@sunair.com

© Copyright 2025 Sunair Co.

Logos on this page are copyrights of their respective companies. The Sunair logo is a registered trademark of Sunair Co.

Leave a comment